Product Detail

Light Weight Design

• Chassis design: For sanitation applications, 510L beam steel is used with multi-condition CAE analysis, reducing chassis weight by 5%.

• Reduced leaf spring design: Suspension uses high-toughness 50CrVa spring steel, reducing leaf springs while maintaining load capacity.

• Precise battery capacity configuration: Battery capacity is optimized using sanitation vehicle operation data, reducing chassis weight and purchase cost.

• Integrated design: Structural components and AC/battery thermal management are integrated to effectively reduce system weight.

Self-Developed VCU

• Efficient energy management: Extends range and operation time with smart regenerative braking.

• Cruise control: Maintains constant speed for low-speed sanitation work, reducing driver fatigue.

• PTO control: Adjust in real time via the multifunction steering wheel with driving and stationary modes.

• Online upgrade capability: Enables batch updates for multiple vehicles via a data platform, improving service efficiency.

Product Appearance

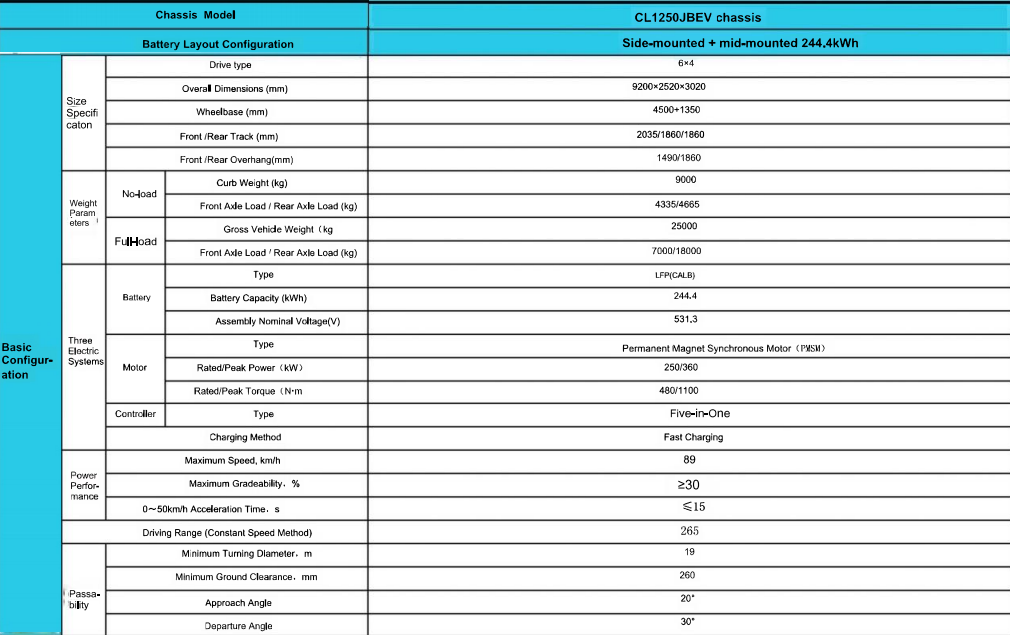

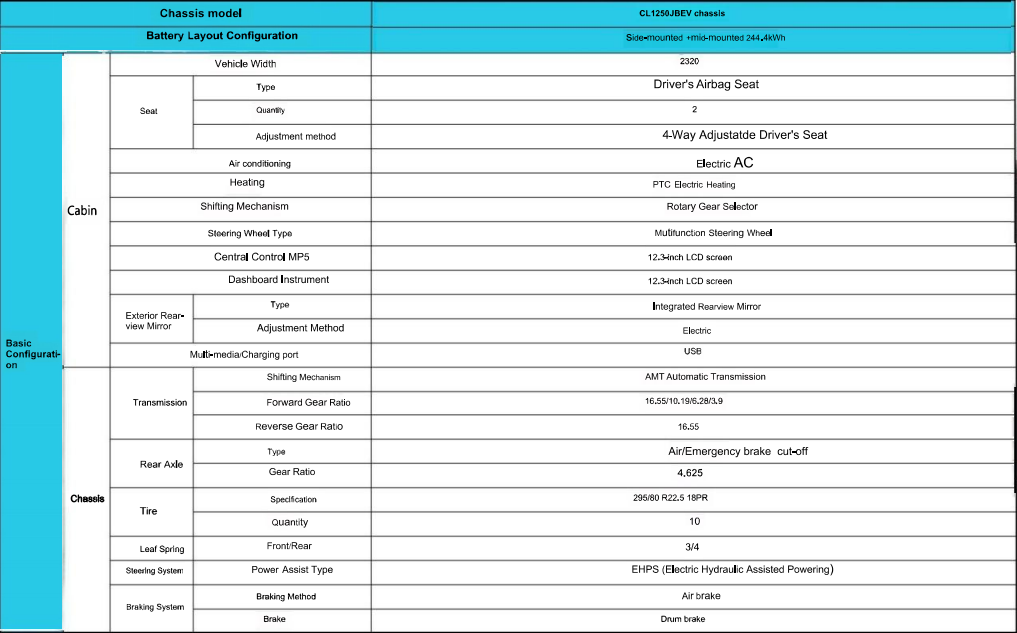

Product Parameters

Applications