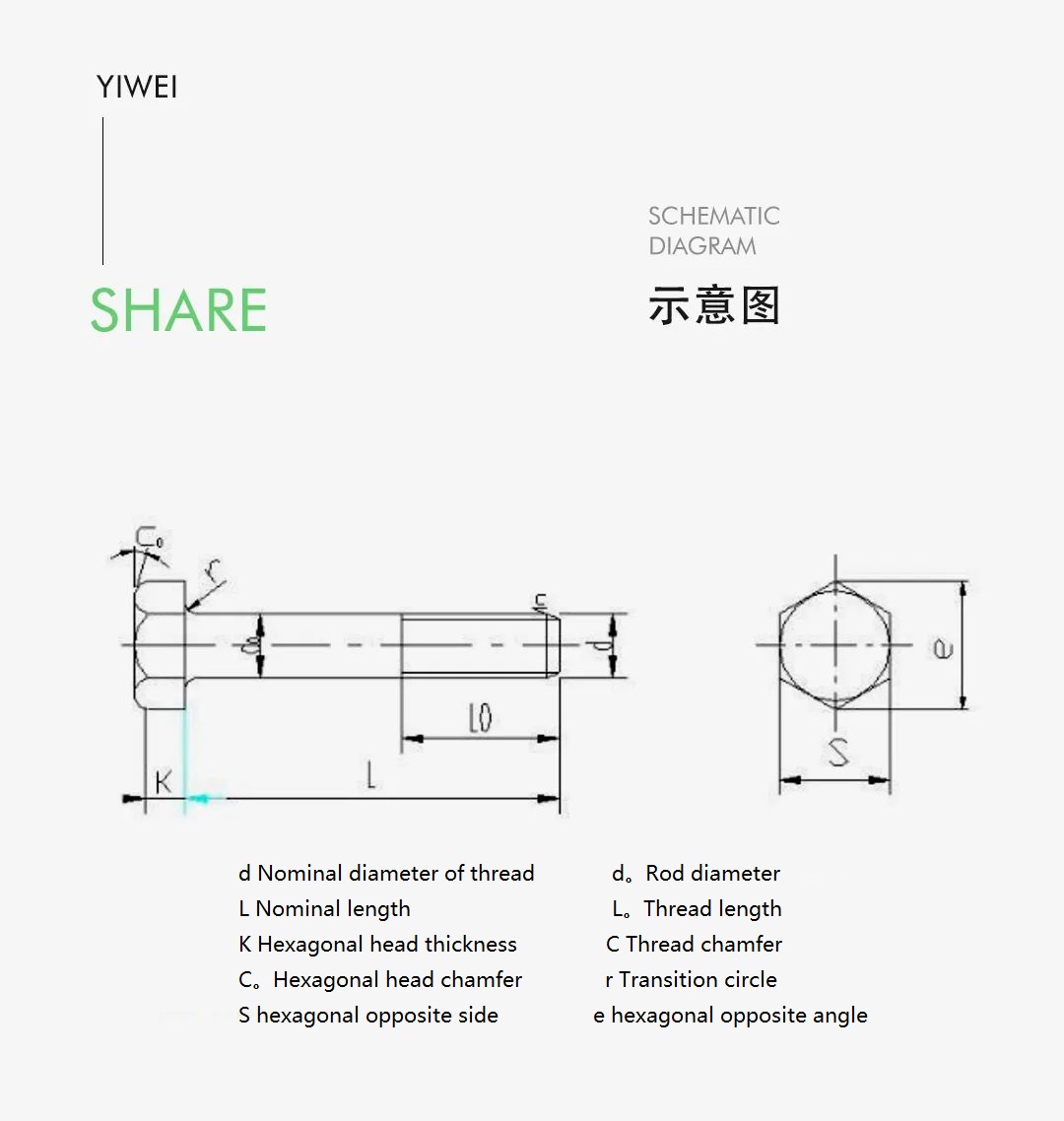

4. Bolt Parts Diagram

6. Markings, Performance Grades, etc.

1. Markings: For hexagonal bolts and screws (thread diameter >5mm), markings should be made on the top surface of the head using raised or recessed letters, or on the side of the head using recessed letters. This includes performance grades and manufacturer’s marks. For carbon steel: The strength grade marking code is composed of two sets of numbers separated by a “·”. The meaning of the number part before the “·” in the marking code indicates the nominal tensile strength. For example, the “4″ in the 4.8 grade indicates a nominal tensile strength of 400N/mm2, or 1/100 of that. The meaning of the number part after the “·” in the marking code indicates the yield-to-tensile ratio, which is the ratio of the nominal yield point or nominal yield strength to the nominal tensile strength. For example, the yield point of the 4.8 grade product is 320N/mm2. Stainless steel product strength grade markings are composed of two parts separated by “-”. The symbol before the “-” in the marking code indicates the material, such as A2, A4, etc. The symbol after the “-” indicates the strength, such as A2-70.

2). Grade: For carbon steel, metric bolt mechanical performance grades can be divided into 10 performance grades: 3.6, 4.6, 4.8, 5.6, 5.8, 6.8, 8.8, 9.8, 10.9, and 12.9. Stainless steel is divided into three categories: 60, 70, 80 (austenitic); 50, 70, 80, 110 (martensitic); 45, 60 (ferritic).

7. Surface Treatment

Surface treatment is mainly to increase corrosion resistance, and some also consider color, so it is mainly for carbon steel products, which generally require surface treatment. Common surface treatments include blackening, galvanizing, copper plating, nickel plating, chrome plating, silver plating, gold plating, dacromet, hot-dip galvanizing, etc.; there are many types of galvanizing, such as blue and white zinc, blue zinc, white zinc, yellow zinc, black zinc, green zinc, etc., and they are also classified into environmentally friendly and non-environmentally friendly types. Each category has multiple coating thicknesses to meet different salt spray test requirements.

Overview of Automotive Standard Parts Products

1). Overview of Automotive Standard Parts

Automotive standard parts have a variety of varieties and are used in the specific production of various components and parts of automobiles, as well as the connection and assembly of various subsystems to form the entire vehicle. The quality of standard parts has an important impact on the overall quality and performance of mechanical equipment, and automobile manufacturers usually have strict review mechanisms and certification standards for fastener supply systems. The huge market size of the automotive industry provides broad development space for automotive standard parts products. According to statistics, a light-duty or passenger car requires about 50kg (about 5,000 pieces) of standard parts, while a medium or heavy-duty commercial vehicle requires about 90kg (about 5,710 pieces).

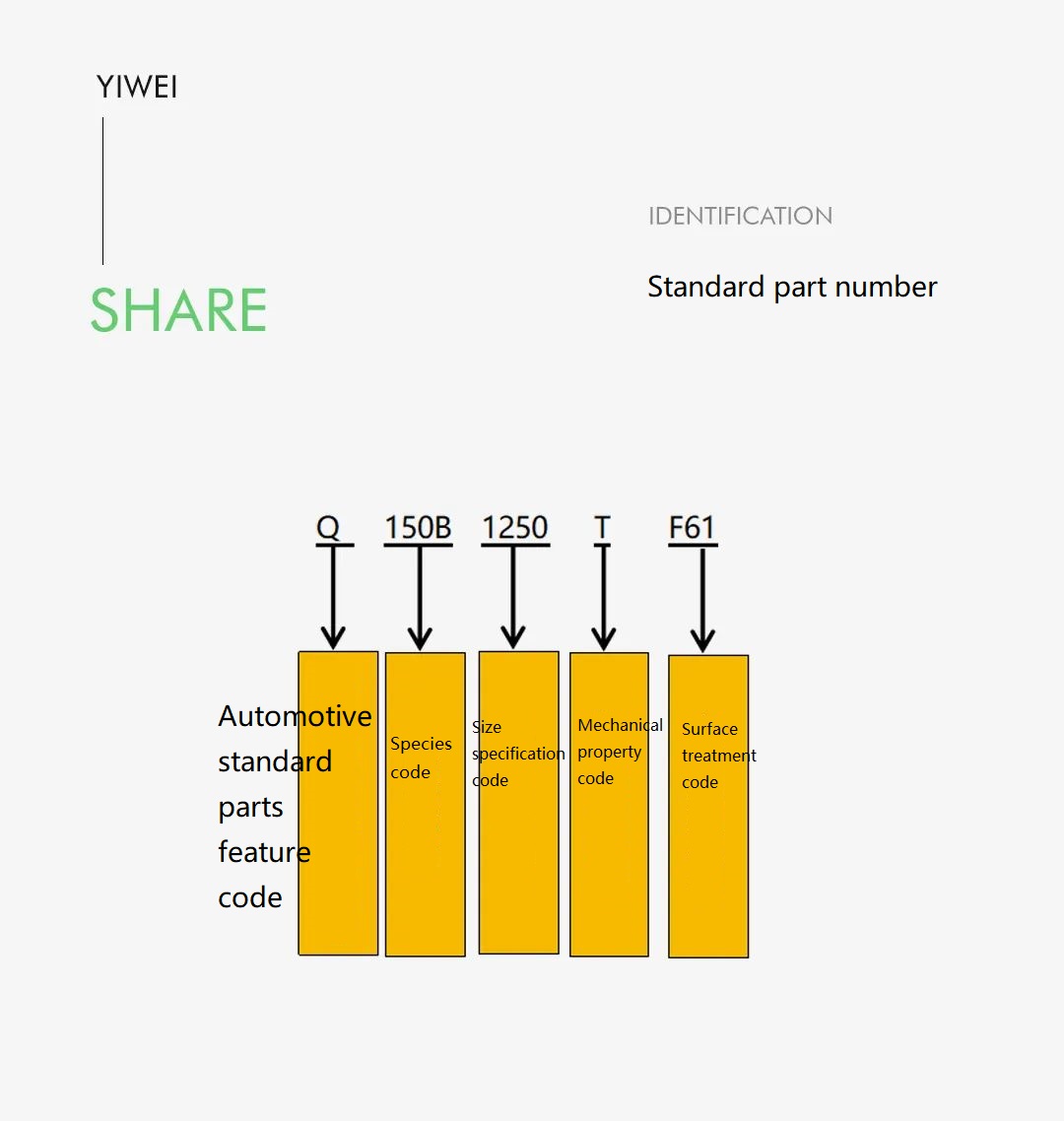

2). Automotive Standard Parts Numbering

Each main engine manufacturer in the automotive industry uses the standard “Automotive Standard Parts Product Numbering Rules” (QC/T 326-2013) to formulate the specifications for enterprise standard parts numbering, and the content remains the same despite variations.

Automotive standard parts numbering generally consists of 7 parts, in order:

- Part 1: Automotive standard parts feature code;

- Part 2: Variety code;

- Part 3: Change code (optional);

- Part 4: Dimensional specification code;

- Part 5: Mechanical performance or material code;

- Part 6: Surface treatment code;

- Part 7: Classification code (optional).

Example: Q150B1250TF61 represents a hexagonal head bolt with a thread specification of M12, a bolt length of 50mm, a performance grade of 10.9, and a non-electrolytic zinc plating (silver-gray) coating. The representation method is as follows:

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Jun-29-2023