02 What are the advantages of HIL platform?

Since testing can be done on real vehicles, why use the HIL platform for testing?

Cost savings:

Using the HIL platform can reduce time, manpower, and financial costs. Conducting tests on public roads or closed roads often requires significant expenses. The time and cost involved in modifying or repairing hardware and software on the test vehicles should not be overlooked. Real vehicle testing requires multiple technicians (assemblers, drivers, electrical engineers, etc.) to be on standby to handle any issues that arise during testing. With HIL platform testing, most of the test content can be completed in the laboratory, and the HIL platform’s user interface allows real-time modification of various parameters of the controlled object without the need for cumbersome vehicle disassembly and reassembly work.

Risk reduction:

During real vehicle validation, there are risks of traffic accidents, electric shock, and mechanical failures when verifying dangerous and extreme conditions. Using the HIL platform for these tests can effectively protect personnel and property, contribute to comprehensive testing of system stability and safety under extreme conditions, and demonstrate clear advantages in controller development or upgrades.

Synchronized development:

During the development of a new project, the controller and the controlled object are often developed simultaneously. However, if there is no available controlled object, the testing of the controller can only begin after the completion of the controlled object’s development. If an HIL platform is available, it can simulate the controlled object, allowing testing of the controller to proceed.

Specific fault handling:

During real vehicle testing, it is often difficult to reproduce certain faults such as hardware damage or short circuits, and there can be associated risks. Using the operational interface of the HIL platform, individual or multiple faults can be reproduced, enabling efficient testing of how the controller handles various types of faults.

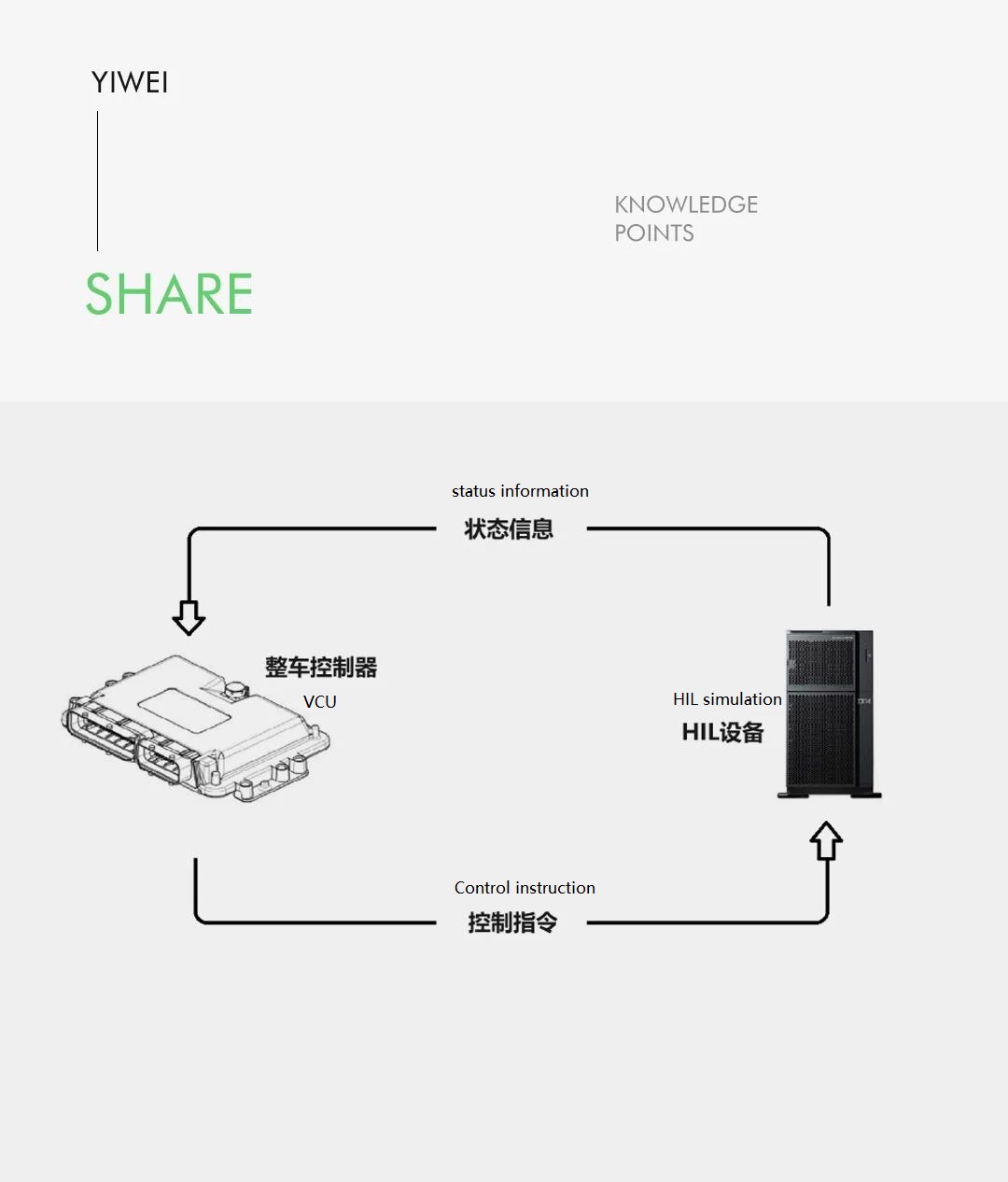

03 How to conduct HIL platform testing?

Platform setup:

Platform setup includes the establishment of both software and hardware platforms. For vehicle testing, the software platform involves building test scenario models, simulation models for sensors, and vehicle dynamics models, as well as test management software. The hardware platform setup requires real-time simulation cabinets, I/O interface boards, sensor simulators, etc. The selection of hardware platform components is mainly based on market choices, as self-development can be challenging.

HIL integration:

Select appropriate testing tools according to requirements and create a suitable testing environment. Then combine the participating algorithm models with the testing environment to form a closed-loop system. However, there is a variety of testing tools available on the market, from different manufacturers, with varying standards and interface data compared to the controller being tested, making integration somewhat challenging.

Test scenarios:

Test scenarios need to cover the majority of use cases and even consider non-reproducible conditions. Sensor signals need to be consistent with real-world situations. The accuracy and comprehensiveness of testing are important indicators of the effectiveness of HIL testing.

Test summary:

The test summary should include: 1. Test environment, test duration, test content, and personnel involved; 2. Statistics and analysis of issues encountered during testing, summary of unresolved issues; 3. Test reports and submission of results. HIL testing is generally automated, requiring only the completion of configuration and waiting for the test to finish, which helps improve testing efficiency and ensure consistency.

Contact us:

yanjing@1vtruck.com +(86)13921093681

duanqianyun@1vtruck.com +(86)13060058315

liyan@1vtruck.com +(86)18200390258

Post time: Oct-09-2023